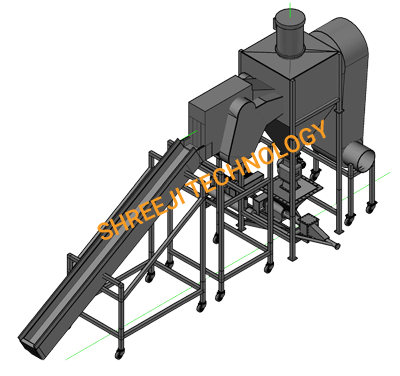

BULKER UNLOADING SYSTEM

We are leading manufacturers and supplier of Bulker Cement Unloading Systems, fly ash bulker unloading system and bulker unloading system. We offer pneumatic conveying systems for cement bulker unloading.

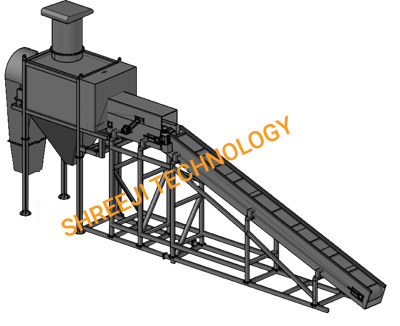

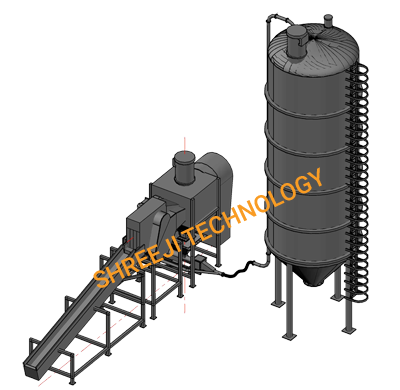

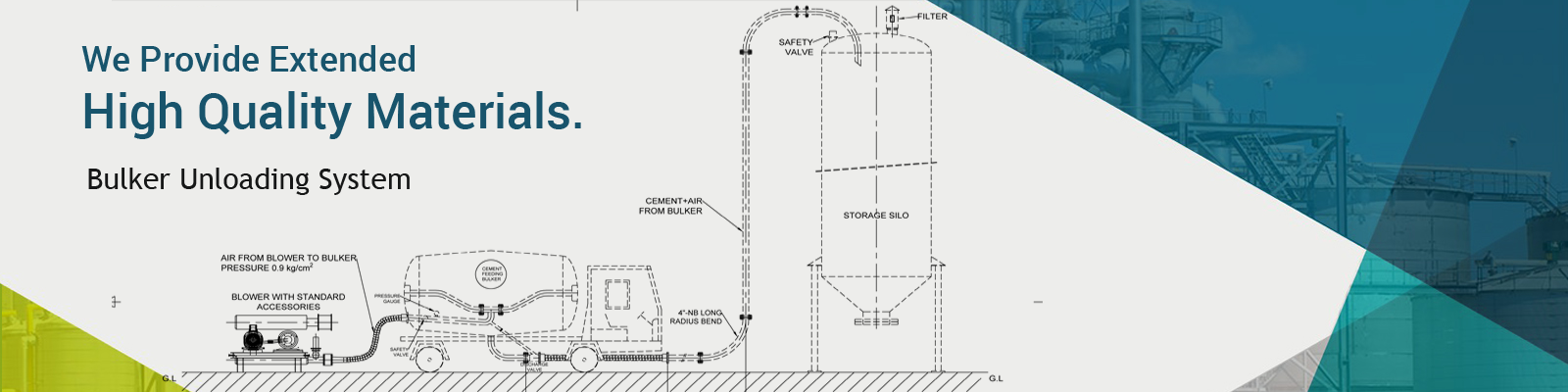

For the Ready-mix concrete sites, where the cement is received in bulkers, a bulker unloading system - pneumatic dilute phase system consists of three distinct components for positive pressure system as following:

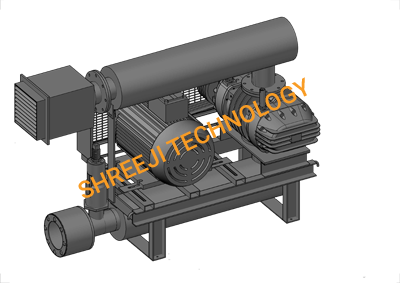

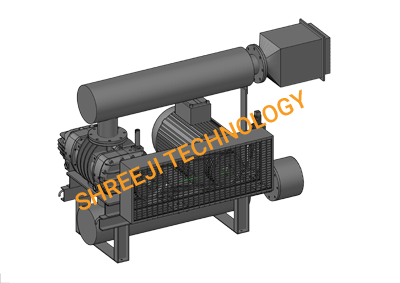

- The Prime mover

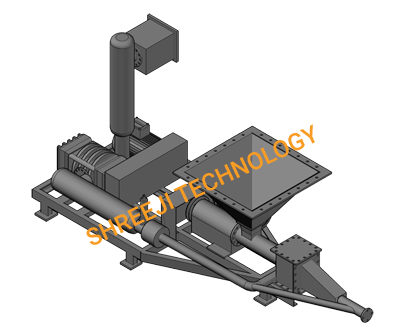

- The bulker unloader with required specification

- The conveying pipes

Each of above with its own characteristics. Control, Safety equipment’s and Instrumentation are also required.

The Bulker unloader is fixed or portable at the plant and the operator connects a rubber hose from the plant air supply to a manifold on the truck. Usually, the air is divided to pressurize the top of the stored material in the storage silo, to fluidise the bottom discharge point, and the main stream is directed to transport it through the pipeline.

The Bulker unloader is fixed or portable at the plant and the operator connects a rubber hose from the plant air supply to a manifold on the truck. Usually, the air is divided to pressurize the top of the stored material in the storage silo, to fluidise the bottom discharge point, and the main stream is directed to transport it through the pipeline.

| Description | : | Bulker unloading system over Horizontal distance of 5 to 7 meters, with an additional vertical lift of 20 to 25 meters. |

| Shreeji Technology | : | Bulker unloading system along with 40 HP/ 50 HP Prime movers, star- delta Starter and conveying pipe sets. |

| Application | : | Cement Bulker unloading / Fly ash bulker unloading. |

| Material Conveyed | : | Cement / Fly ash. |

| Bulk Density | : | 1200 to 1600 Kg/m3. |

| Product Destination | : | Storage Cement silo / Fly ash silo. |

Live Image

Our Products

Shreeji Technology is dedicating to provide a product quality, value and services which meets a customer need. Optimum use of computer aided design software , 3D Modeling analysis softwares to achieve quality assurance procedures.